Digging into the complexity of IMU data processing

Working with IMU data can be challenging. Software systems make a number of assumptions and overcoming environmental factors that effect the hardware instrumentation can be difficult. Understanding how your system works can be key to combating software limitations, optimizing hardware specifications, and accurately identifying when something is wrong.

Not all IMU systems are the same. Check out these 5 things that you should know about your IMU data:

How are environmental factors handled

The magnetometers in IMUs are highly sensitive to magnetic fields in the measurement environment, which can make your data unusable. Some systems provide correction algorithms to reduce magnetic interference. You should know if you have control over when these algorithms are applied and, if so, understand when it is appropriate to apply them.

How to get a good calibration

Software models require calibration to the sensor placement by using a predetermined static calibration pose. You need to know your system’s required calibration position and ensure your subject can assume the position. If not, and angle offset will be present in your measurements.

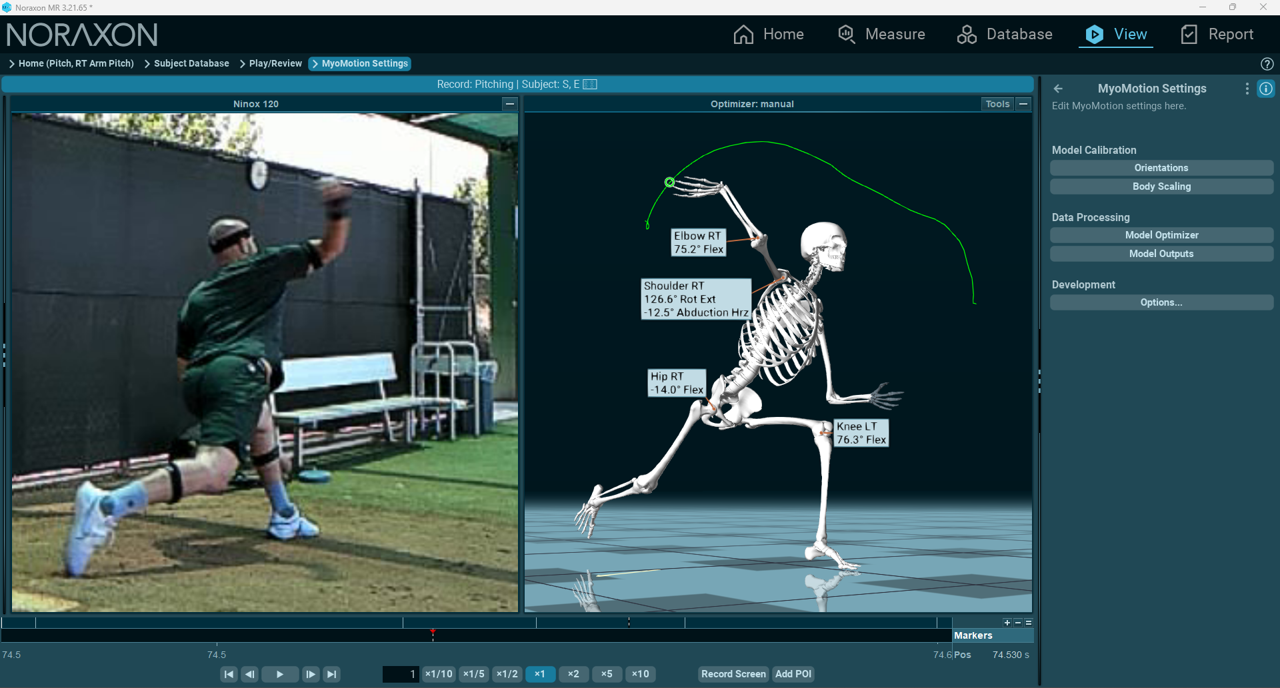

What kinematic model and constraints are in place

Software systems use rigid body models to generate biomechanical data and animate skeletal avatars based on subject motion. You should know what model is being used and if any movement based constraints are placed on your data. These factors can affect how you interpret your data and if you can make comparisons to other data sets.

Does it integrate and synchronize with other hardware

Understanding why your subject is moving the way that they are often requires looking at other types of biomechanical data (e.g. force or EMG). You should know if your system has the capability to acquire and time synchronize other types of biomechanical data to your IMU data measurements.

What is required for sensor placement

You should know how many sensors are required to calculate your metrics of interest and exactly where are on the body each sensor must be placed.